Safety is the foundation of every food service business. The atmosphere and experience can only be built on a foundation of trust in your establishment’s food safety practices. Businesses that don’t take food safety seriously, risk spreading foodborne illness in their community, impacting their reputation–and their bottom line.

Keeping your establishment food safe means mastering the basics, from personal hygiene to preventing cross-contamination and more. We’ll cover all of the general tips and tricks you need to know so you and your customers never have to worry (no safety helmets required).

Keep It Clean

Clean kitchens start with the basics: a clean and tidy space, systems in place for keeping it that way, and good habits ingrained in your staff. There are the obvious steps, like training staff in proper handwashing techniques, and the less obvious, like a comprehensive waste management plan that includes pest control.

Kitchen & Equipment Cleaning

Food safety starts with ensuring surfaces touched by your ingredients are clean, including countertops, cutting boards, and prep stations. Your staff must understand the nuances between cleaning, sanitizing, and disinfecting. While often used interchangeably, these terms have distinct meanings and should be applied accordingly in different kitchen areas.

Here’s a quick breakdown:

- Cleaning is the first step, where obvious dirt and debris are removed. A kitchen can be clean but not sanitary, the latter being what health inspectors look for.

- Sanitizing reduces germs on surfaces or objects to a safe level, as dictated by public health standards or requirements. It kills bacteria that can cause foodborne illness, but not viruses.

- Disinfecting uses chemicals to kill any remaining germs on surfaces or objects, further lowering the risk of spreading disease. This does kill viruses and helps prevent the spread of disease (like a cold or the flu).

Beyond hygiene, effective waste management is essential due to the significant waste generated in kitchens, including food scraps, expired ingredients, and packaging. Kitchens can enhance sustainability by implementing waste separation practices for compostable food scraps and recyclables and offering eco-friendly to-go containers to reduce food waste. Opting for sustainable to-go packaging, such as reusable, recyclable, or compostable containers, further contributes to environmental preservation.

Another resource available to Gordon Food Service customers is InnoServ. InnoServ is your trusted expert in environmental cleanliness and beverage equipment, products, services, and solutions to support your operation and keep your employees and patrons healthy, safe, and refreshed.

Personal Hygiene Matters

Thorough handwashing is critical in a commercial kitchen–a dollop of soap and a quick rinse in the sink doesn’t cut it. Proper hand washing technique is required; everyone on your team should be trained and drilled on it.

The Centers for Disease Control (CDC) outlines five steps for proper hand washing:

- Wet hands with clean, running water (any temperature), then turn off the tap and apply soap.

- Lather soap by rubbing hands together; include the backs of hands, between fingers, and underneath fingernails.

- Scrub for at least 20 seconds. (Sing “Happy Birthday” twice for a handy timer.)

- Rinse hands well under clean, running water.

- Dry hands with a clean towel or air dry them.

Hands must be washed before, during, and after food preparation, especially after handling raw meat, flour, or eggs, as well as after tasks like handling garbage, cleaning with chemicals, or eating. This frontline defense against contamination, including foodborne illness, can be supplemented with high-quality personal protective equipment (PPE) such as gloves, aprons, and hair nets. However, PPE does not replace proper hand hygiene, and hands should still be washed before and after wearing gloves to prevent contamination.

Keep It Separate

Another hallmark of food safety is keeping various ingredients and finished dishes separate from one another. This helps with temperature control and in preventing cross-contamination.

Maintaining food safety involves keeping ingredients and finished dishes separated to control temperatures and prevent cross-contamination. Temperature control is critical, as bacteria thrive in the Temperature Danger Zone (41°F to 135°F), emphasizing the importance of the two-hour rule for food left at room temperature, which reduces to one hour if temperatures exceed 90°F.

Proper training on heating, cooling, and freezing food is essential, noting that not all foods can be re-frozen without compromising quality. Preventing cross-contamination includes understanding the difference between cross-contamination and cross-contact, particularly regarding food allergens. Establishing a comprehensive plan to address food allergens communicates your commitment to customer safety and can transform your establishment into a trusted dining destination for those with food allergies.

Cook It Correctly

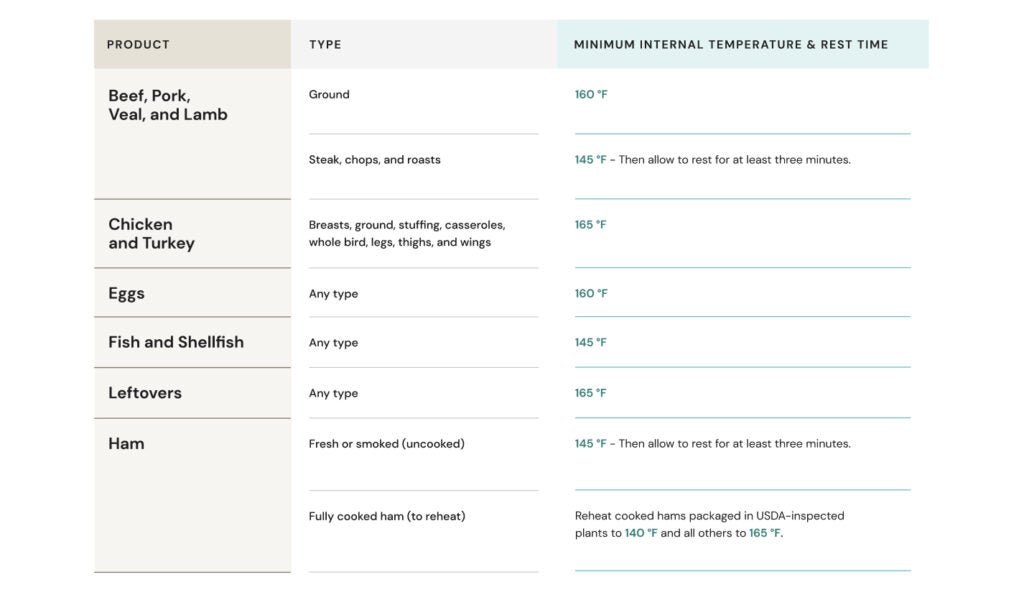

If food is safely handled with clean hands in a clean environment, it then needs to be cooked to the correct internal temperature to be considered safe to eat. The U.S. Department of Agriculture (USDA) has a chart with examples:

Ensuring foods are cooked to the correct internal temperature means having the right kind of food thermometers on hand and keeping them calibrated. Appliance thermometers must also be checked and calibrated regularly.

Keep It Cool

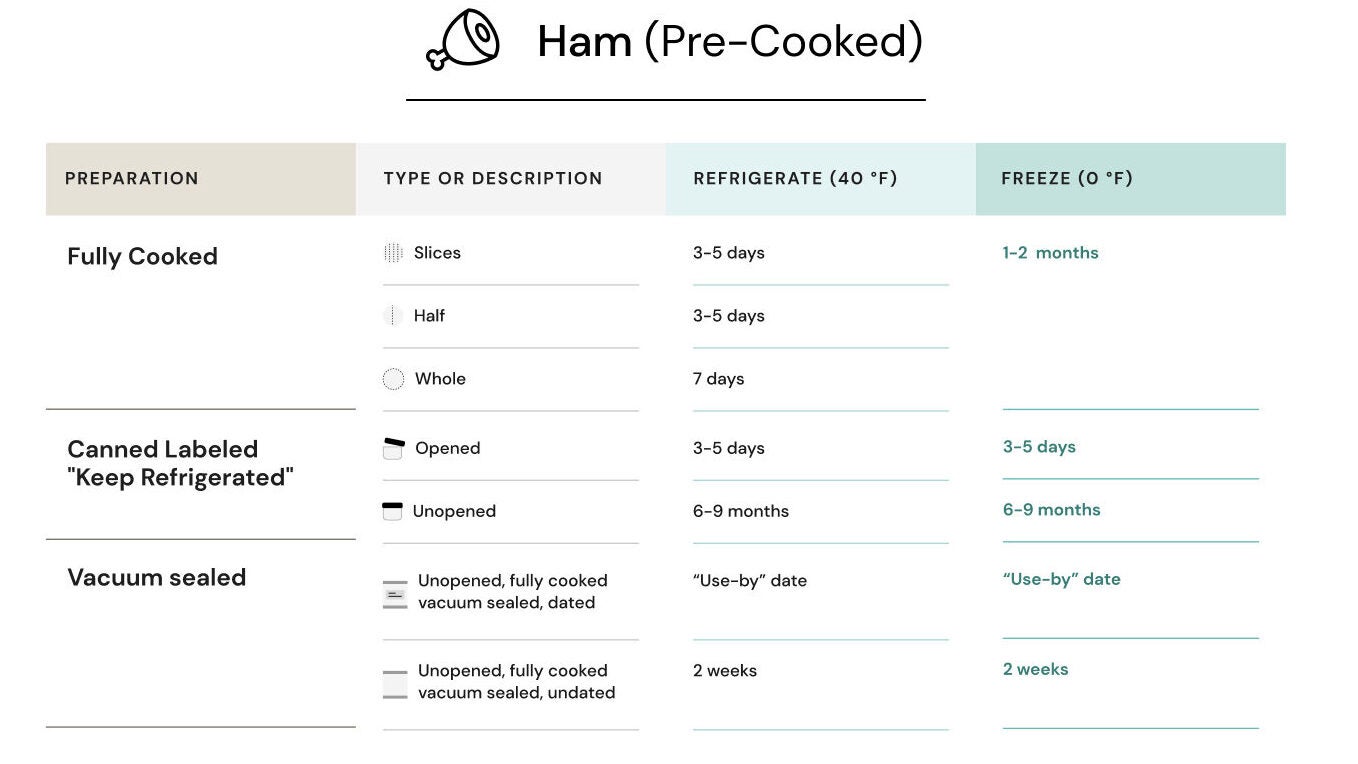

The USDA also has extensive guidelines around proper cold storage, both for temperature and the length of time a food item can be safely refrigerated or frozen. Here’s an example using ham:

Keep comprehensive charts in the kitchen in a place that’s easy for staff to access, especially while they’re onboarding. Making food safety easy to follow increases the likelihood no steps will be compromised or skipped in a busy kitchen during rush.

Keep a Record

You’re doing lots of great work to keep your kitchen clean, and now there’s just one more thing: keeping track of it all. Keep thorough documentation of staff training, inspections, audits, and supply inventory to streamline compliance during health inspections. Advanced tracking may involve monitoring thermometer calibration and implementing a composting schedule. Store all documentation alongside crisis management and communication plans in a centralized location accessible to key staff for emergency preparedness.

Final Sweep

Keep these general tips and tricks handy for your staff to reference whenever needed–especially during onboarding. Be sure to emphasize the importance of food safety above everything else in your kitchen until it’s a deeply ingrained part of your company culture.

That dedication will show up in the rest of the work your staff does–and customers will appreciate the level of thoughtful attention to their health and the subsequent experience that you provide.

Interested in food safety training for your team? Learn about group purchases through Trust20 for Teams today!