In the valley just south of Salinas, California, where the cool marine layer settles off the Monterey Bay, the people at Church Brothers Farms are hard at work with the rising sun since sunrise. The cool, dewy morning hours are ideal for harvesting broccoli.

The Church Brothers team never lets early hours stand in the way of collecting produce at its peak of freshness and flavor quality is their promise. From planting to growing to harvesting to processing – Church Brothers Farms is committed to sustainable and socially responsible practices. It’s exactly why this family farm is part of the Markon family of vegetable and fruit suppliers.

After weeks of growing in the fertile soil, nurtured by cool nights, warm days and West Coast sunshine, the moisture-dappled crowns of crisp broccoli are ready. So is the Church Brothers’ team. The long, blue harvesting and processing wagon spans about 10 rows as it crawls across the broccoli field. The field crew chops the broccoli at its stalk, trims away a few leaves, and transfers the produce to the wagon, where it is packaged, cooled and readied for delivery. Click here to shop some of the premium produce from the Church Brothers.

It’s a field-to-fork story with many layers. It’s a story worth explaining, especially in an era when people want to know about the food they eat.

What Makes Markon Special?

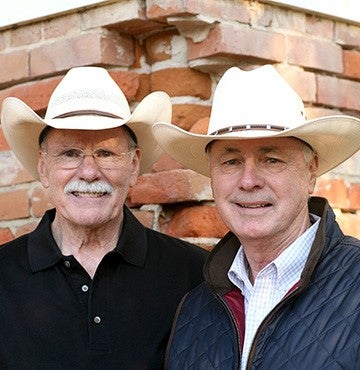

The Markon difference starts with growers. Church Brothers Farms, a family-operated business with primary products such as broccoli, cauliflower, celery, iceberg lettuce and romaine lettuce, was founded in 1999 by brothers Steve and Tom Church.

“The produce business is hard work. Tom and I learned our work ethic in the lettuce fields as teenagers. Our mom would fix us three salami sandwiches each for lunch and they were usually consumed before noon,” Steve Church said. “We worked with Oaxacans from Mexico. … They were hard-working people who made sure Tom and I kept up with their fast pace. Work ethic: we learned it, we kept it, and still embrace it today.”

Jeff Church, Chief Operating Officer, says Church Brothers Farms values Markon’s role as a bedrock partner in the broccoli program.

“In an industry where crops and markets can be volatile, it is essential to have good partners who you can rely on, week in and week out, that are committed to consistently buying the product when it is ready to harvest,” he said. “They work closely with our field supervisors to ensure that the quality in the box meets their standards.”

There are similar Markon grower stories across the portfolio of products in the Markon First Crop, Ready-Set-Serve, and Markon Essentials lineup. Markon Vice President of Marketing Nelia Alamo explains it’s all about partnerships.

“Markon is not merely a purchasing organization. When customers buy Markon brand produce, they are getting nearly 40 years of expertise that includes long-term relationships with multi-generational farming companies, strict food safety regulations, daily inspections in the fields and processing facilities, transportation temperature monitoring, and educational tools for best practices,” Alamo said. “The importance of these partnerships cannot be overstated.”

A Foundation of Stewardship

Markon only partners with growers who use sustainable practices, such as crop rotation, energy conservation, waste reduction, water conservation, recycling and more. Markon and its growers are committed to being stewards of the farming business and the planet.

In an era of concerns about the impact of industrial farming, it is refreshing to know there are many small growers working hard to uphold the high standards it takes to be part of the Markon brand.

“When people outside of the produce industry see the logos and labels of big companies, they may assume that the products come from nameless, faceless fields,” Alamo said. “This is not the case with Markon’s grower-partners. In fact, the grower community in the primary growing regions of California and Arizona are most often families that have farmed the Salinas, San Joaquin, Santa Maria, and Yuma Valleys for generations.”

Alamo explains that Markon benefits growers by managing food safety inspections, marketing and distribution so smaller farms can do what they do best: grow fresh fruits and vegetables.

“Working together in this way means that the generational knowledge of local families is preserved and passed down, improving the growing methods and product quality,” she said.

Communication and Responsibility

Consistency and transparency are among the biggest benefits to the relationship between Markon and its growers. It matters at the production level, it matters to the chefs who create with ingredients, and, especially, it matters to those who consume the food.

The inspection process is key. Quality assurance inspectors travel from field to field, six days a week, ensuring that the produce packed in Markon cartons is the best available.

“Because our inspectors visit these fields and facilities so frequently, they have developed bonds with our suppliers’ teams, from farm managers down to the actual harvesting crew members,” Alamo said. “This kind of rapport allows us to understand real-time issues and get ahead of any potential challenges.”

The inspection process is part of the Markon 5-Star Safety program.

“It is the most comprehensive in the industry, using quantifiable metrics to ensure the fresh fruits and vegetables we ship are delicious and safe,” Alamo said. “5-Star Food Safety is based on specifications, inspections, and information at five key points: fields, facilities, transportation, distributor warehouses, and the operator kitchen.”

Here is a breakdown of each area and what it means for safety:

Star 1: Fields

- Third-party audit reviews for Good Agricultural Practices.

- Detailed specifications.

- Daily inspections.

- Water testing.

Star 2: Grower Facilities

- Third-party audit reviews for good manufacturing practices (GMP) and Hazard Analysis Critical Control Points (Ready-Set-Serve only).

- Regular inspections.

- GMP observational visits and product quality standards verification.

- Water testing.

- Environmental monitoring program.

Star 3: Transportation

- Temperature monitors on trucks originating in Arizona, California, Idaho, New Mexico, Oregon, Texas (South Texas), and Washington.

Star 4: Distributor Warehouses

- Dedicated quality assurance programs.

- Warehouse temperature zones in use.

- Third-party inspections.

Star 5: Operator Kitchens

- Products can be traced back to field level.

- Regular mock recalls are conducted to verify traceability.

- “Best If Used By” dates on all Ready-Set-Serve inner and outer packaging.

- Storage and handling information on packaging.

- Cooler icons on packaging easily identify appropriate cooler storage areas.

- Food safety educational tools are available through a sales representative.