This article originally appeared in the Gordon Food Service Foodscape publication.

Is it worth paying restaurant employees to peel potatoes? Should they spend time cutting and mixing salad greens? The current labor climate raises these questions. The answer could be as simple as ready-to-use products.

As operations start to add more dine-in traffic to already busy takeout and delivery schedules, employees are beyond busy. Combine that with the likelihood of being short-staffed and the phrase “time is money” gets real.

Add in employee turnover or a no-show during a busy shift and you’ll spend time and money training team members to avoid sacrificing quality. After all, you can’t afford to disappoint customers, especially as they’re just returning to the dining-out scene.

Find your labor vs. cost balance

It’s common knowledge that precut, ready-to-use (RTU) items cost a little more than buying whole vegetables or carving your own meats. You pay a cost when the supplier slices veggies, washes lettuce, packages salad blends, or expertly and consistently trims steaks.

It’s a balancing act. Money spent on RTU products saves labor in your kitchen. A plate-cost analysis might show it takes 15 cents per serving to make a menu item but saves 20 cents in labor. That five cents goes right to your bottom line.

The time you save handling labor has other benefits. Instead of spending hours in the prep kitchen, your team can focus on creativity and be happier and more challenged. The resulting new menu concept or beautiful plate presentation adds value to your brand.

How does it work?

If you prepare a realistic plate cost model, including time spent on preparation, you can assess whether it’s worthwhile to incorporate value-added key products. Start by asking three questions:

- Is my time (or my employees’ time) worth doing repetitive work that does not add value to my dishes?

- Can I maintain the consistency of my dishes considering staff issues that may happen?

- Can my staff properly manage some items and keep dishes profitable?

A “no” answer to any of those questions should have you considering alternative solutions.

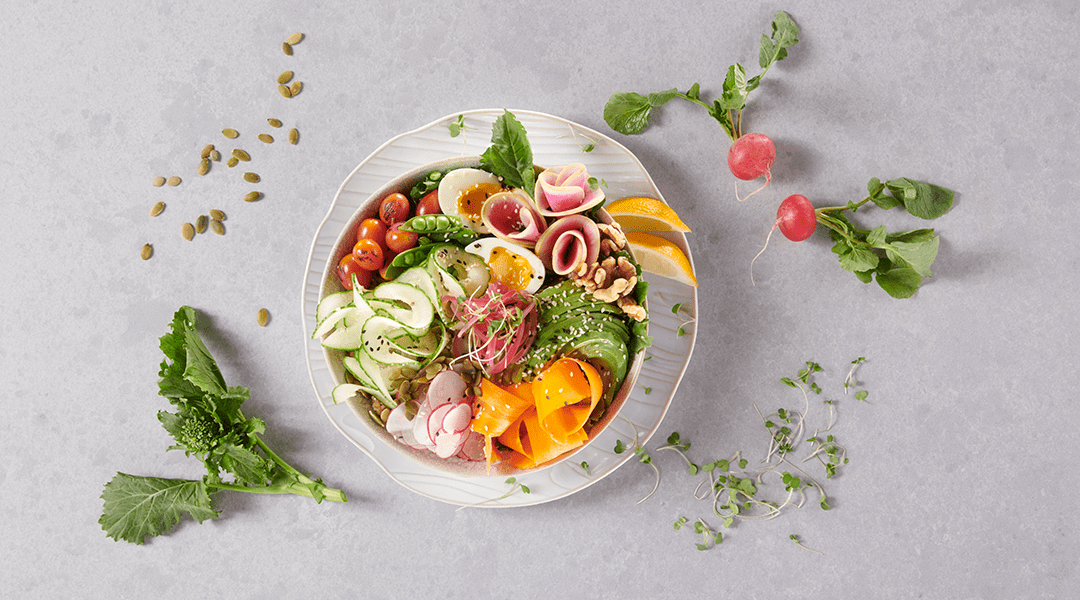

Produce possibilities

Markon Ready-Set-Serve produce is a proven cost saver. Markon has created a cost calculator so operators can check the savings on chopped, peeled or prewashed fruits and vegetables. The savings go beyond labor.

“In addition to labor savings, operators save money by maximizing the yield—you don’t pay for parts that get trimmed and thrown out,” says Gordon Food Service Business Solutions Specialist Juan Del Corral. “You actually get more usable product per pound and really good shelf life.”

Markon guarantees quality with a 5-Star Food Safety Audit Program, and prewashed RSS produce meets HAACP standards, saving your staff cleaning time and monitoring.

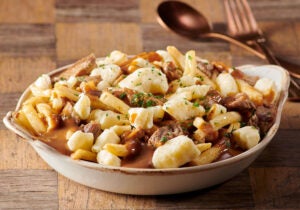

Protein profitability

Protein is usually the most expensive item on the plate. Buying whole cuts of meat at the right price seems economical, but there are risks that can compromise profitability:

- Inconsistency and miscuts

- Cost of unused by-products

- Price volatility

By working with a pre-cut program, you pay for 100% yield and ensure consistent weight and quality with every piece. This makes it easier to calculate the real food cost of each plate without any surprise, resulting in a better control of your sales.

Halperns’ provides a lengthy list of meat and seafood options, from the finest Angus beef to fresh, sustainable seafood to pork, poultry and game from boutique suppliers around the world.

Your Gordon Food Service Sales Representative can introduce you to ready-to-use options that offer menu benefits and labor savings.