We all have high hopes for our businesses. But as the saying goes, hope isn’t a business strategy—accurate plate costing is. If you aren’t mastering your numbers, you aren’t running a kitchen; you are running a charity.

Foodservice operators have all experienced that familiar panic during a Saturday night rush: the kitchen is screaming, tickets are hanging, and you realize you are down to your last five pounds of applewood smoked bacon. You’re in an ingredient emergency. Those ingredient emergencies add up – and stick you with a profit emergency at the end of the month: The dining room was full, the staff was busy, but when you look at the bank account, it’s empty.

In this guide, we are going to talk about how to level up in restaurant management by moving past the “gut feeling” approach to ordering ingredients, plating dishes, and managing food costs: we are exploring why restaurants fail, identifying the margin munchers that steal profits, and provide a data-driven framework to engineer a menu that ensures you can bring home the bacon.

The 50% Reality Check

The statistics are sobering: only 50% of restaurants make it to 5 years. Here is the twist: Most of them didn’t fail because their food was bad. They didn’t fail because their service was slow. They failed because they forgot to check how much they were paying to generate revenue.

Step 1: Identify the Margin Munchers

Imagine holding a $100 bill. That represents the profit from your last table. Now, imagine taking a pair of scissors and snipping off corners of that bill.

- Snip: That is the extra cheese the kitchen didn’t measure.

- Snip: That is the price of eggs going up while your menu stayed the same.

- Snip: That is the to-go packaging you didn’t account for in your pricing.

Now, you’re left with shreds of profit that could have been greater with a little bit of planning.

The Heavy Hand Tax

One of the biggest culprits in a restaurant kitchen is what we call the Heavy Hand Tax. It is the extra 2 ounces of sauce, the handful of fries, or the unmeasured cheese. You might think, “It’s just a little extra cheese, the customers love it.” But let’s look at the math. If you over-portion shredded cheese by just $0.20 per plate, and you sell 50 plates a day, you are losing $3,650 a year—that is the cost of a new commercial reach-in cooler.

| Over-portioned Ingredient | Cost Per Ounce | Daily Loss (50 Plates) | Annual Loss (Pure Profit) | Equivalent to… |

| Shredded Cheese | $0.20 | $10.00 | $3,650 | A new commercial cooler |

| Sliced Deli Turkey | $0.45 | $22.50 | $8,212 | A high end convection oven |

| Cooking Oil | $0.08 | $4.00 | $1,460 | Your annual pest control contract |

| Sirloin Steak | $0.75 | $37.50 | $13,687 | A part time dishwasher’s salary |

| Aioli/Sauce | $.15 | $7.50 | $2,737 | 500+ “free” guest appetizers |

The Accessories

Never forget about the plate flair – those costs add up too. The pickle spear, the logo-branded wax liner, and that Instagram-worthy bamboo sandwich pick all cost money. If you miss the mark on your costing by a mere 50 cents per dish, and you sell 100 dishes daily, you are waving goodbye to $18,250 a year.

Ingredient Prices

Food costs are not static. According to the USDA, food costs rose 3.8% in 2025 and are predicted to rise another 3% in 2026. If your menu prices stay the same while the cost of eggs, beef, and oil climbs, your margins disappear.

Step 2: Stop Guessing, Start Calculating

Too many operators play a guessing game. They look at a competitor’s burger price and say, “I’ll charge a dollar less.” But do you know your Cost of Goods Sold (COGS)? To get a grip on your budget, you need to calculate your food cost percentage using this formula:

Beginning Inventory + Purchased Inventory – Ending Inventory = COGS

Once you have your COGS, divide it by your total food sales to get the percentage of food cost compared to your Cost of Goods Sold. Profitable restaurants usually land between 28% and 35%. If you are sitting at 40%, you have a problem.

However, knowing your total percentage isn’t enough: you need to know the cost of every single item on your menu. Take the below formula:

Food Cost of Ingredients x Amount Sold = Total Food Cost Per Dish

Then, divide that cost by the sales price to see if that item is actually making money.

Step 3: Operational Solutions: Tools, Not Rules

You cannot be in the kitchen 24/7 watching every plate being built. You need systems. Instead of policing your staff with rules, give them the tools to succeed.

- Color-Coded Scoops: Don’t tell a line cook to use “3 ounces.” Give them a blue scoop that is exactly 2 ounces or a green scoop that is 4 ounces. This eliminates confusion.

- The Pre-Portion Rule: If it can be weighed, weigh it during prep. Fries, pasta, shrimp, and cheese should be bagged in exact portions before the rush starts. This stops the “heavy hand” when the tickets start flying.

- The Reference Plate: For your top 5 high-volume items, take a photo of the perfect portion on a scale. Print it and tape it to the station. A picture is worth a thousand arguments.

Step 4: Menu Engineering

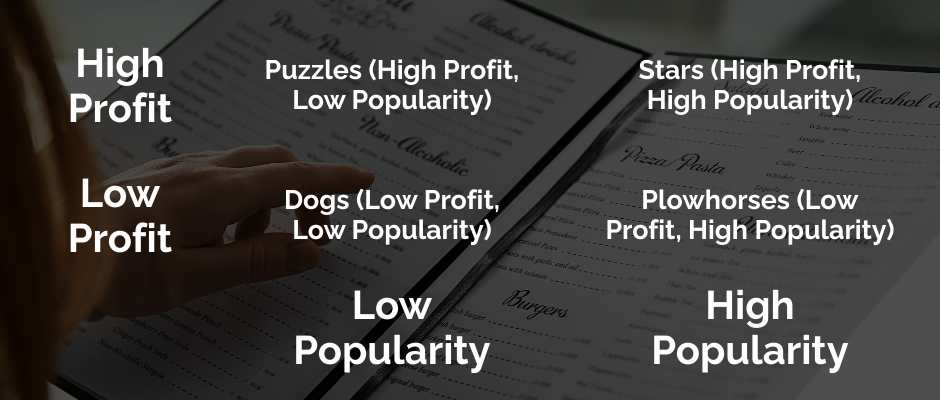

Once you have accurate costs, Menu Engineering steps up to the plate. This is the strategic process of using data and psychology to design your menu for maximum profit. To do this, you must categorize every menu item into one of four quadrants based on Profitability and Popularity:

- Stars (High Profit, High Popularity) These are your winners. You make good money on them, and customers love them. Promote them aggressively. Highlight them on the menu using visual cues like boxes or bold text. Do not mess with the recipe or the price—just keep selling them.

- Plowhorses (Low Profit, High Popularity) These items fly out of the kitchen, but they don’t leave much money in the till. You need to re-cost these immediately. Can you decrease the portion size slightly? Can you raise the price by 50 cents? Try moving them to a less visible area of the menu so they aren’t the first thing people see.

- Puzzles (High Profit, Low Popularity) You make a great margin on these, but nobody orders them. Solve the mystery. Is the description unappealing? Is the price too high? Try offering them as a limited-time special to test if better marketing drives sales.

- Dogs (Low Profit, Low Popularity) These items are losing you money and taking up fridge space. Kick them off the menu. If you absolutely must keep one for a regular customer, reformulate the recipe to make it profitable.

The Psychology of Design

Beyond the math, how you design the physical menu matters when employing Menu Engineering principles.

- Eye Gaze Motion: Customers don’t read menus like books. Their eyes scan. On a tri-panel menu, the “Golden Triangle” (center, top-right, top-left) is where the eyes go first. Put your Stars there.

- Visual Cues: Use boxes or specific colors to draw attention. Green suggests freshness; orange stimulates appetite.

- Ditch the Dollar Sign: Avoid using the ($) symbol. It reminds people they are spending money. A simple “14” performs better than “$14.00”.

Connect Your Systems Together

One of the best ways you can control food costs is by using technology. Connect your purchasing, recipes, and inventory with your Point of Sale (POS) system. Why? because technology helps you identify waste and track variances instantly. 74% of operators plan to spend more on technology in the next six months. If your ideal food cost is 28% (based on recipes) but your actual food cost is 30% (based on inventory), that 2% variance is money walking out the door. Gordon Ordering helps you do this: log into your account and check out our recipe calculator, inventory worksheet, and more to help you engineer your menu for success.

Your Next Steps

You don’t have to overhaul your entire business overnight. Start small to see big results.

- Identify Your Top Sellers: Ask your sales rep or check your POS to find your top three selling menu items.

- Cost Them Out: Calculate the exact plate cost for just these three items using the Recipe Calculator inside Gordon Ordering. Don’t forget the garnish, the sauce, and the packaging.

- Check the Value: Remember, price gets customers once; value brings them back – and Value doesn’t mean “cheap.”

- Be Consistent: The difference between a good meal and a return customer is 90% consistency: same quality, same temperature, same plating. Create consistency with training, technology, and operational tools.

Reducing your food cost percentage by just 3% can equal increasing your sales by 10-15%. Your next vacation, your next piece of equipment, and your next successful year are hidden right inside your menu costs. Reach out to your sales rep today to learn how Gordon Food Service can help you find that bacon.